All You Need To Know About

What is Aluminium Fabrication

Aluminium fabrication is a critical industrial process that includes shaping, assembling, and finishing aluminium into various structures or products. The low weight, strength, and corrosion resistant nature of Aluminium makes it one of the most versatile materials used in metal industries globally. It is widely accepted in felds like Architecture, Transport, Aerospace and in making consumer goods.

With this guide from Manufacto India you will understand what fabrication of aluminum is, how the process works on it, its types, applications of it and how it is helpful in infrastructure framework and manufacturing.

Types of Aluminium Fabrication

Aluminium fabrication is concerned with the production of metal structures using various processes such as cutting, bending, welding, and the final assembly of various components. These processes transforms raw materials of aluminium into tangible building parts or products aligned with the construction designs. Important Properties of Aluminum:

Lightweight yet strong

Corrosion-resistant by nature

Excellent thermal and electrical conductivity

Eco-friendly and recyclable

Easily transformed through fabrication

Process of Fabricating Aluminum

Th manufacturing process of aluminium is comprised of some basic steps depending on the product to be made:

Designing and Planning

Like any preference, manufacturing uses CAD models together with accurate graphical representations as the basis for cutting, welding, and assembling which makes sure there is no malfunction during the actual work.

Cutting

Aluminum plates and extrusions are cut to the required size using saws, shears, and scribing wheels amongst others.

Forming and Bending

This initial cut is followed by the bending and shaping step using a roller or brake press. In this stage, precise complex geometries and customized profiles are constructed.

Machining

Holes, threads, and grooves can be formed by the application of sequentially controlled precision tools or CNC machines.

Assembly and Welding

Fastening or welding is done at this phase. Aluminum will make its weld joints that are distinct because of the nature of a metal’s heat properties.

Finishing and Surface Treatment

Finishing processes done after fabrication are often aimed at improving the durability as well as the external appearance of the aluminum, they include anodizing, powder coating, polishing and painting.

Different Types of Aluminium Fabrication

Depending on the scope of a project and the needs of the industry, various methods of aluminum fabrication may be employed.

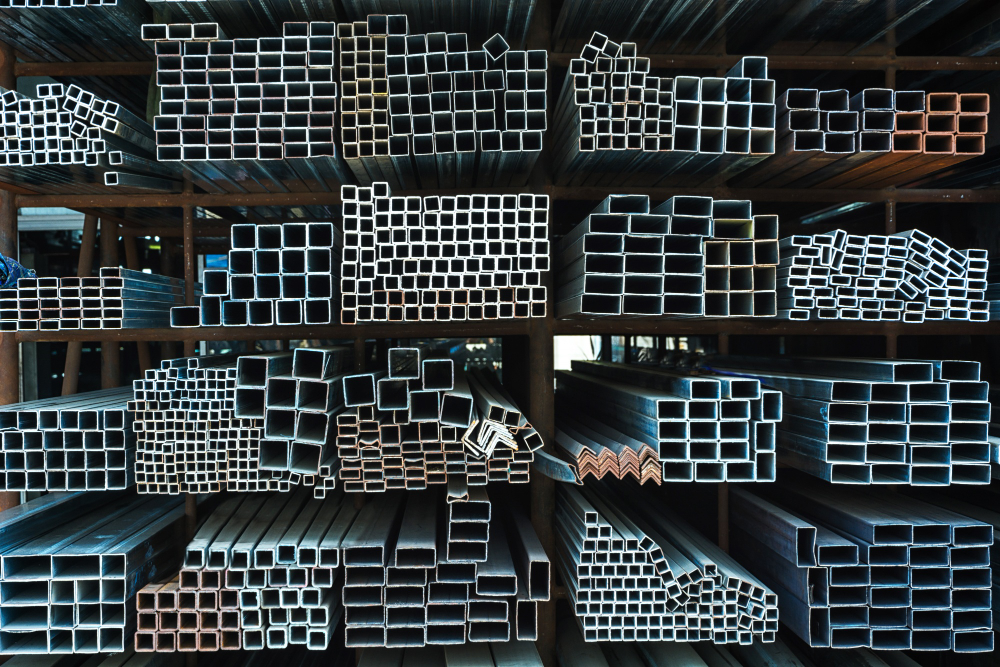

• Aluminum Sheet Fabrication

Aluminum sheets can be used for roofing, facade cladding, or other architectural purposes.

• Aluminum Extrusion Fabrication

Applied to window frames, railings, beams, and other structural components.

• Structural Aluminum Fabrication

Custom fabrication of building and infrastructure vertical elements which are considered to be heavy-duty or load bearing.

• Precision Fabrication

Used in the automotive, electronic, and aerospace industries which require tight tolerances.

Uses of Aluminium Fabrication

The flexibility of aluminium and its qualities result in wide applications of industries such as:

🏗 Construction Industry

- Aluminum formwork systems

- Curtain walls and cladding

- Windows, doors, and railings

- Structural supports and roofing systems

🚗 Automotive & Transportation

- Lightweight body frames

- Trailers and panels

- Fuel-efficient vehicle parts

🛩 Aerospace

- Aircraft fuselage and wing structures

- Interior components and fittings

🏢 Architecture & Interior Design

- Designer ceilings, partitions, and staircases

- Furniture and modular fittings

⚙️ Industrial Equipment

- Machine frames, housings, and enclosures

- Storage racks and conveyors

Benefits of Aluminium Fabrication

Strategically investing in aluminium fabrication pays off majorly due to the following reasons:

Durability

Aluminium is corrosion-resistant while static in harsh weather, extending its life with time.

Lightweight

Significant reduction of structural load surpassed only by steel.

Sustainability

Aluminium is 100% recyclable with no loss of quality. Supports sustainable construction initiatives.

Aesthetic Appeal

Aluminium does not corrode therefore maintains a clean modern look suited towards architectural and designed finishes.

Customizability

Aluminium can be fabricated into complex shapes and fitted with surfaces tailored to the client's needs.

Reasons to Consider Manufacto India for Aluminium Fabrication

At Manufacto India, our forte lies in aluminium formwork and fabrication braces in construction and infrastructure development. We design our aluminium systems to enhance speed and safety while improving sustainability at construction sites, ensuring innovation and quality at all levels.

Every component is designed and fabricated within-house to ensure the best possible standards in mechanical performance, durability, and aesthetics of the product.

Final Thoughts

Aluminium fabrication, while being a process of altering a particular alloy, also stands as a very important aspect revolving around efficiency, power, and sustainability modern industries strive for. Along with building advanced machinery equipment, aluminium is essential in creating a high-rise tower for the very first time in one’s life, ensuring a big leap forward towards the future.

If you are looking for the most reliable name for aluminium fabrication or formwork systems in India, look no further. Reach out to Manufacto India for precision and performance as promised.